Projects

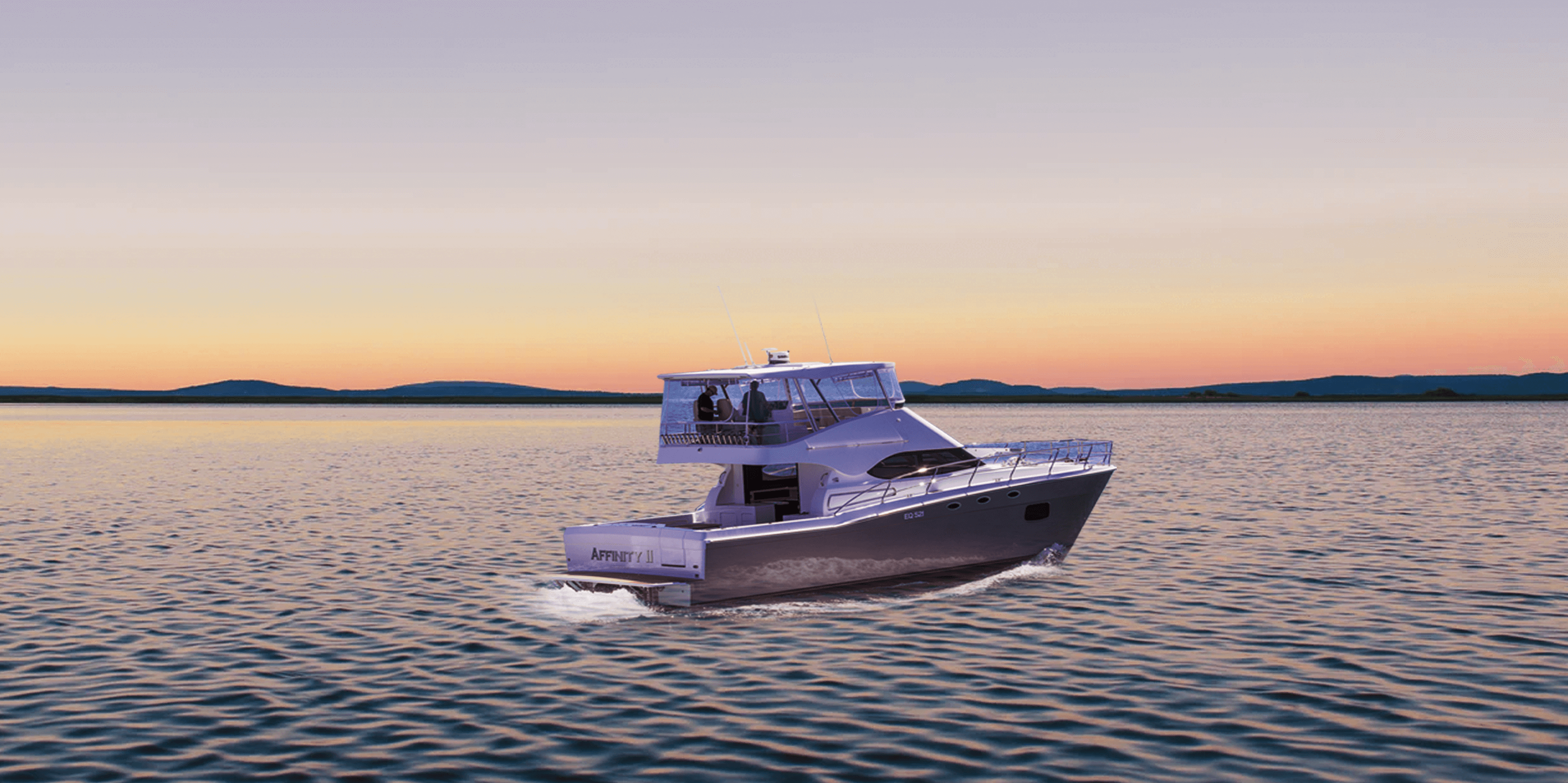

East Cape Marine 14m Sport Fishing Catamaran - Affinity II

| Length Overall | 14 m |

| Beam | 4.85 m |

| Fuel | 2000 L |

| Engines | 2 x 300hp |

| Speed | 24 knots |

| Noah Thompson Design | www.noahthompsondesign.com |

| The Cat Factory | www.catfactory.com.au |

Design Concept

Designed by Noah Thompson of Noah Thompson Designs in New Zealand, the boat was commissioned by a local Perth gentleman with a passion for fishing. The design brief called for a fuel efficient vessel of the same size and weight of his current monohull. A lengthy study of hull shapes with POD drive engine packages was conducted and a custom design, with planing hull and the Volvo IPS-400 inboard Performance System was decided on to tick all the required boxes.

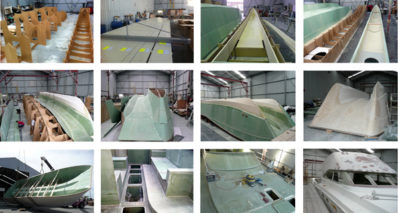

Construction

The latest Noah Thompson Design power cat, built by Lloyd Powell and Kate Tarrant of The Cat Factory in Fremantle, the luxury 14m sport fishing cat, Affinity II was built from a DuFLEX / AIREX Structural Foam Kit over a 20 month period with an “out of shed” weight of 11 tonnes which, even when loaded with fuel, water, payload and passengers, was well under the original design weight.

Because of previous experience and construction success, Noah based the design for construction with ATL Composites lightweight DuFLEX panels with a structural foam core. The design was transformed into a DuFLEX Kitset and the panels were manufactured by ATL, CNC routed into kit form, including all structural and interior parts cored with a variety of densities to optimise the engineering and performance in specific areas, and shipped to The Cat Factory for construction.

DuFLEX construction significantly reduced the weight of the vessel, addressing the need to reduce fuel consumption without sacrificing comfort or performance.

Because of previous experience and construction success, Noah based the design for construction with ATL Composites lightweight DuFLEX® panels with a structural foam core. The design was transformed into a DuFLEX Kitset and the panels were manufactured by ATL, CNC routed into kit form, including all structural and interior parts cored with a variety of densities to optimise the engineering and performance in specific areas, and shipped to The Cat Factory for construction.

DuFLEX construction significantly reduced the weight of the vessel, addressing the need to reduce fuel consumption without sacrificing comfort or performance.

Additional reinforcements and taping were laminated with ATL’s high performance KINETIX® Laminating resins and all bonding, filleting and fairing were completed with WEST SYSTEM® resin and hardeners with a combination of WEST SYSTEM powder modifiers as required.

WEST SYSTEM 410 Microlight fairing compound is 30% lighter and less porous than other fairing compounds on the market and 30% easier to fair than phenolic microballoons.

“It’s not often you see a vessel with a paint job so finely detailed that you can see the ocean reflection in it. For anyone who has bogged and faired a boat will tell you it is a labour of love to get perfection.” Noah Thompson – Designer

The design layout was developed closely with the owners who had owned large boats in the past. The idea was to keep the cabins as large as possible with full head room, large doors, plenty of light, and stowage under the floor. The main cabin is open plan with the galley opening onto the aft deck for ease of cooking and serving. The lounge and adjoining seat offer a relaxing space. The owner requested that the flybridge is accessed from inside the cabin, and works well for security. Interior components were supplied as a DuFLEX / AIREX® C70.75 Kit with a 10mm foam core reinforced with a 600grm quadraxial laminate.