vdL Composites returns to METS in 2024

Lightweight Wonder

vdL Composites at METS 2023

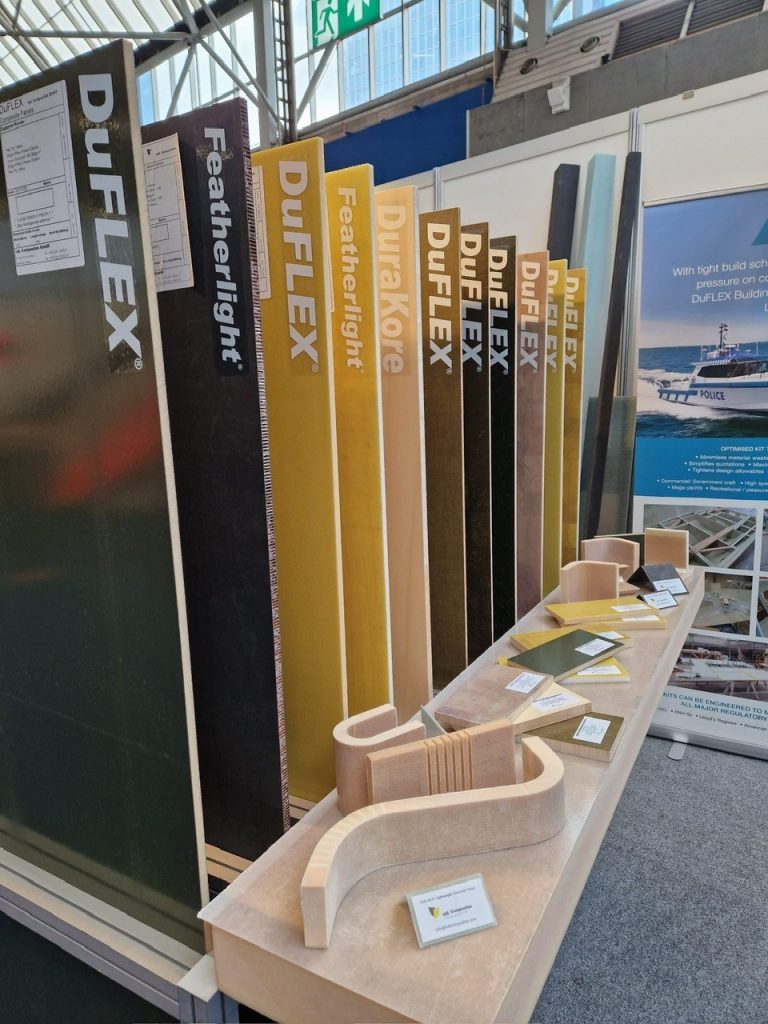

ATL Composites heads to METS 2023

Red Car Marine resto relies on DuFLEX

A classic Sydney trawler that operated for 30 years in Tasmania as Marconi’s Cross out of Hobart is being given a new lease on life by the experts at Red Car Marine in the fortuitously named suburb, Goodwood in Hobart.

James Watson runs Red Car Marine and he and his team are meticulously restoring the 14.75-metre timber fishing vessel for its Sydney owners.

Built in 1948, the historic vessel is a veteran of tuna fishing, trawling and towing fish pens, before going up for sale.

As James explains, “Her new owners have commissioned a total refit, including the wheelhouse, aft lounge, sliding doors and interiors to turn it into a pleasure boat for cruising the Hawkesbury River, and eventually some passage making to Whitsundays.”

The design brief has expanded over time to include the aft lounge with covered awning, and below decks, berths in the foc’s’le, and two additional berths in the fish hold.

James, a shipwright, drew up the plans, and with his two assistants, Dean and Paul, have set to work on the refit project.

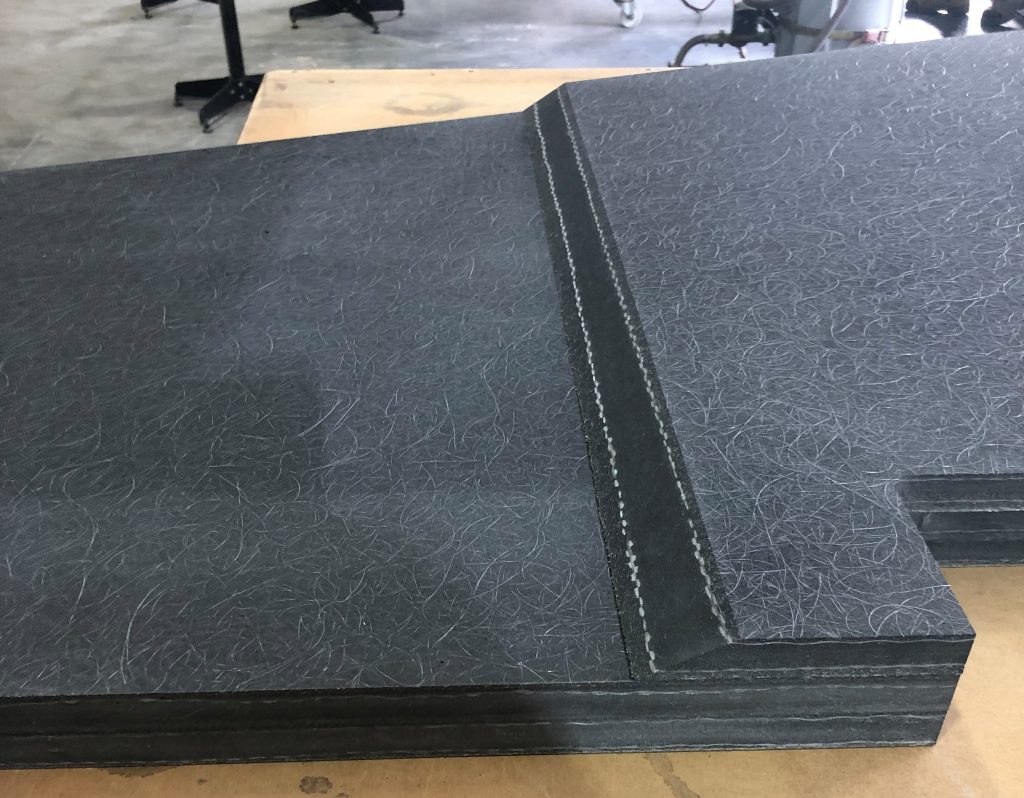

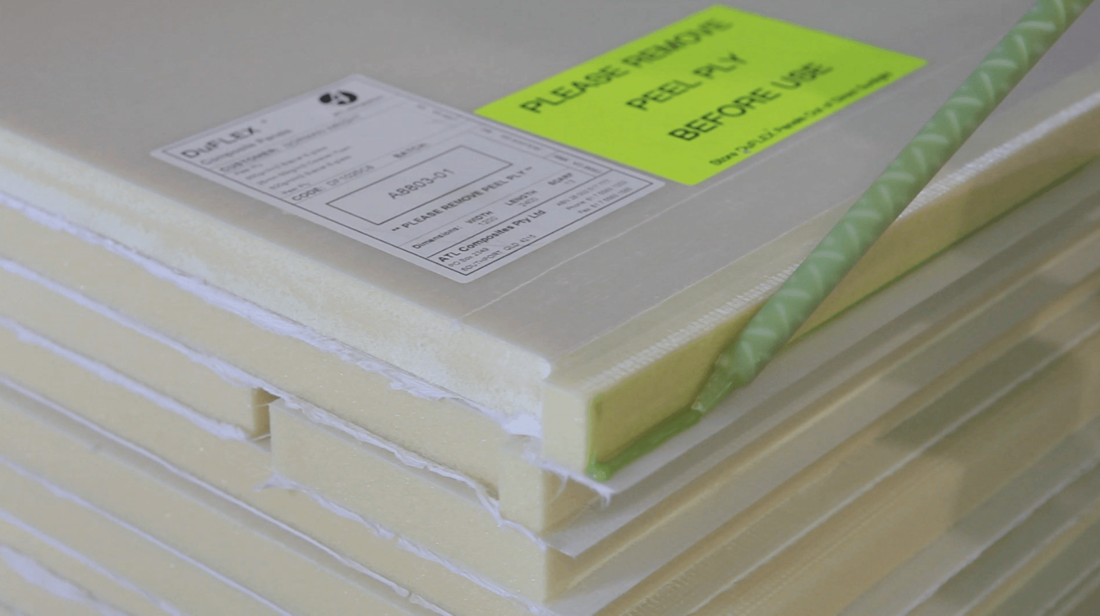

“The bridgedeck is the first part,” he says. “Mark Richards, who is acting as the owner’s representative, and I chose to use composite board from ATL. The DuFLEX panels cored with 40mm Divinycell H80 Structural Foam are ideal for use on top for their lightweight and strength. They weight 50 or 60kg lighter than plywood and lining. Plus, the added advantage of ease of installation, cutting down labour time.”

Custom built to meet the specific size and shape for the bridge deck, the DuFLEX panels will be shipped in eight parts and joined on site at Red Car Marine for optimum freight efficiency and handling.

“We simply install the panel, fabricated with a specialty finish on the underside which results in no pinholes, and then go direct to sand and paint. It cuts down prep time by a truckload of hours. We are using exposed wooden beams underneath with the modern top for a really beautiful look.”

James is a loyal advocate of WEST SYSTEM products, which he describes as “our go to products”. He swears by 105 epoxy resin and 206 slow hardener, as well as Techniglue R15, a toughened, thixotropic epoxy paste with increased peel strength.

“ATL products are great quality, and the team at ATL provides good support and communication to tailor advice for each project. I’ve always found them very helpful. Tasmanian Marine Distributors – Distributors for ATL products – introduced us to Lorraine. We met her at the Australian Wooden Boat Festival and she’s very personable.”

The Marconi’s Cross restoration is on track to be delivered back to her owners in January 2024 in time for summer cruising on Sydney Harbour.

Follow the progress over the coming months: news.atlcomposites.com.au

Marconi’s Cross on Instagram @marconi_trawler

Composite Panels for Speed and Efficiency in Boat Racing

Boat racing is a thrilling sport that requires exceptional speed and performance. To be successful in this sport, each component of a racing boat must be optimised for maximum efficiency. The use of composite panels, which offer a variety of benefits that help to improve speed and performance, is an important aspect of the design of a boat.

In this blog, we’ll take a closer look at composite panels and how they help improve the performance of a racing boat.

What are composite panels?

Composite panels are created by bonding two or more different materials together to form a single, lightweight, and strong material. Some of the most common materials used in boat racing include carbon fibre, Kevlar and fibreglass. These materials are known for their high strength-to-weight ratio, which makes them ideal for use in applications where weight is a critical factor, such as boat racing.

How do composite panels improve speed and performance?

- 1. Reduced weight: One of the most significant benefits of composite panels is their lightweight nature. Boats that are constructed using composite panels are much lighter than those made from traditional materials like wood or metal. This reduced weight means that boats can achieve higher speeds with less power, allowing racers to push their boats to the limit without sacrificing performance.

- Increased stiffness: Composite panels are also known for their high stiffness, which allows boats to maintain their shape and resist flexing. This stiffness improves boat handling, making it easier to control the boat and maintain speed around corners and in rough water conditions.

- Enhanced durability: Composite panels are incredibly durable and can withstand the high stresses and strains that occur during boat racing. Unlike traditional materials, composite panels do not rot, warp, or corrode, ensuring that the boat remains in top condition for longer periods.

- Improved aesthetics: Finally, composite panels offer a sleek, modern look that is ideal for boat racing. Their smooth surface finish and ability to be moulded into intricate shapes allow boat designers to create unique and aerodynamic designs that can improve the boat’s speed and performance.

Conclusion

Composite panels are an essential component of modern boat design and help improve speed and performance in boat racing. Composite panels enable racers to push their boats to their limits and achieve the highest levels of performance possible by reducing weight, increasing stiffness, improving durability and enhancing aesthetics. As boat racing continues to evolve, we can expect to see even more innovative uses of composite panels that will enhance the sport and its competitive nature.

ATL Composites is a leading supplier in Australia of advanced composite boards, materials and engineering for the construction of high-performance, lightweight structures for the marine, automotive, architectural, civil and industrial tooling markets. Get in touch with us today to learn more about our products and services!

Composite Panels: Benefits in Marine Industry

ATL Composites has been supplying the marine industry for over 35 years and has the experience and materials technology to provide practical solutions to optimise structures for weight, strength, and stiffness. Our experience includes CE/ISO, Lloyds Register, ABS, DNV, Germanischer Lloyd, BV and Australian Standard compliance for racing yachts, catamarans, ferries, patrol craft and pleasure vessels.

The team of structural engineers at ATL Composites understand all aspects of composite technology, with a focus on engineering to allow for practical fabrication solutions and to optimise structures for weight, strength, stiffness and affordability for marine applications. Keep reading to learn more about the benefits of composite panels for your vessel.

Weight

Weight is essential in marine applications for achieving performance, stability, and safety. The large panel-forming capabilities of ATL Composites provide the ideal solution for weight reduction. Our lightweight marine panels are a premier composite material that performs exceptionally well in a wide range of applications ensuring cost-effective, lightweight solutions.

Strength

Composite panels are designed to meet the toughest marine standards and have a higher strength-to-weight ratio than traditional materials. Our engineer’s design, fabricate and manufacture composite panel solutions ideal for a wide range of maritime applications including boats, yachts and other vessels. Our end products are lightweight, durable and corrosion-resistant.

Stiffness

The combination of lightweight materials, such as carbon fibre and fibreglass, with our proprietary composite technology, ensures that each panel is stiffer than aluminium or steel panels of the same size. Our advanced solutions are designed to provide maximum structural stiffness for applications requiring a high strength-to-weight ratio.

Durability

ATL Composites takes pride in the superior quality and durability of our panels, which are designed to withstand the rigours of harsh marine environments. Our composite panels are water, UV, and corrosion-resistant, ensuring a long service life even in harsh conditions. This provides a more cost-effective solution for marine and industrial applications, as the panels do not need to be replaced as often. Additionally, our materials provide excellent resistance to vibrations and shock, making them ideal for use in high-performance vessels.

Cost-savings

Due to their lightweight construction, our panel solutions offer significant cost savings over traditional aluminium or steel panels. Composite panels’ lighter weight results in lower fuel costs and improved vessel performance, making them an ideal choice for boat owners looking to maximise efficiency while minimising expense.

ATL Composites is a leading supplier in Australia of advanced composite boards, materials and engineering for the construction of high-performance, lightweight structures for the marine, automotive, architectural, civil and industrial tooling markets. Get in touch with us today to learn more about our products and services!

Composite Panels: Improving Automotive Efficiency

As technologies evolve to meet the constant demand for higher productivity, autoclave curing is progressively being replaced by alternative processing solutions such as compression moulding, standard infusion and high-pressure, fast-injection RTM. Epoxy resins, speciality core materials and high-performance reinforcements are now providing new structural solutions that will radically alter the way cars and other vehicles are designed and built.

Our in-mould coatings are used in the high-performance motor-sport industry, specifically V8 Supercars, to meet the high strength and toughness requirements. Manufacturers are increasingly focusing on alternative technologies and materials to optimise and adapt to the automotive industry’s requirements. That is where our expertise in the development of new and innovative composite processes comes into play.

The benefits of these new composite panels materials mean that cars can be made lighter, more efficient and with greater reliable than ever before. The possibilities are virtually endless as these composites can reduce weight, increase strength and durability, improve crash safety performance, reduce production costs and enable a wide range of vehicle configurations. In addition to this, our in-mould coatings allow us to create a range of finishes on the vehicle components that are both aesthetic and durable.

Our team of experienced engineers is dedicated to finding new and innovative solutions for automotive OEMs and their suppliers while working closely with them to ensure their needs in terms of quality, performance and cost are met. Our commitment to research, development and innovation has enabled us to stay at the forefront of the industry, delivering quality components that meet or exceed OEM requirements.

The automotive industry is constantly evolving and we are proud to be part of this evolution. We strive to remain ahead of the curve in our industry, offering the latest technology, materials and production processes to ensure that OEMs can get the best possible outcomes for their product. Our experienced team is dedicated to providing quality products and services, with a focus on customer service and satisfaction.

We have experience in the design and manufacture of composite panels material for refrigerated cars and trucks, emergency vehicles, utility vehicles and even campervans. Our dedication to quality materials, production processes and customer service has earned us the reputation of being a leader in our field.

ATL Composites is a leading supplier in Australia of advanced composite boards, materials and engineering for the construction of high-performance, lightweight structures for the marine, automotive, architectural, civil and industrial tooling markets. Get in touch with us today to learn more about our products and services!